Destructive Testing measures the physical properties of a material

Whether required for certification, evaluation or peace of mind, testing is a fundamental process that ensures your equipment can be used safely and is fit for purpose.

Materials, components and assembled products can all be put through either Destructive Testing (DT) or Non-Destructive Testing (NDT), or both.

Reliance Hexham is NATA accredited to offer a range of both DT and NDT methods used to determine the component’s safety and spot any weaknesses in the products supplied.

Destructive Testing and its Applications

Destructive Testing measures the physical properties of a material, including but not limited to, resistance to impact, yield strength, and ultimate tensile strength.

DT is also employed for testing of the safety factor of equipment; this verifies the ratio between common usage stress and failure point. As the name suggests, in the process of testing, DT pushes the sample material to such an extent as to destroy or damage it to the point of being unsafe to use.

This type of testing is, therefore, best suited to materials, samples of production lots, or mass-produced goods, whereas one-of-a-kind pieces of equipment are best tested by an NDT technique.

Failure to properly test materials, components and equipment can lead to severe financial and legal repercussions. On the financial side, downtime cost can well run into the millions AUD per day due to critical equipment becoming inoperative.

On the legal front, non-compliance with testing requirements can result in economic penalties to the company and, in extreme cases, even personal liability.

In Australia, mine companies are regularly audited by the Mines Department with the aim to ensure safe working standards for the miners.

For instance, the required safety factor from most mining equipment is 10 to 1, meaning that the breaking load should be ten times greater than the usual working load. We call this over-engineering for safety.

Wherever equipment failure is liable of causing potentially costly consequences, testing should never be omitted.

Process for Destructive Testing

Reliance Hexham is accredited by NATA, National Association of Testing Authorities, to carry out and issue certification for Destructive Testing in accordance with our scope of accreditation.

Break Load testing is used for the evaluation of load handling, rigging and tensioning systems, as well as for design validation.

Break load tests are carried out to the sample’s failure, with the aim of understanding its structural performance or material behaviour under increasing loads.

This type of testing also provides design validation from theoretical failure loads to actual failure loads, as well as the calculated modes of failure.

We also carry out a range of non-destructive testing, including Proof Load testing, which you can read about here.

Breaking Load Testing

We at Reliance Hexham believe that pushing a piece of equipment all the way to its breaking point is fundamental to understanding its reliability.

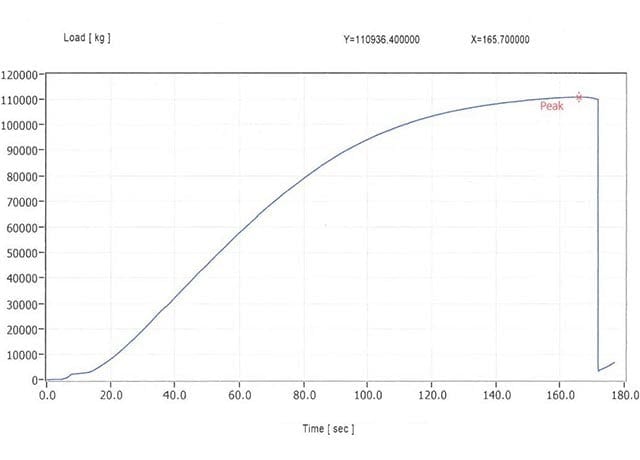

Breaking Load testing essentially consists of applying a load to the specimen, usually several tonnes, and slowly increasing it until the final point of failure.

This procedure may last a few seconds or minutes and tests the specimen’s ultimate strength.

While this process is being carried out the computer software will log a live graph that is then printed in a report for evidence and future reference.

Types of graphs that can be produced include:

- Force / Elongation

- Force / Time

- Stress / Strain

- Stress / Time

- Elongation / Time

- Strain / Time

In the past, we have issued certification and reports for applications as diverse as heavy-grade mining equipment, cranes and, as it happens, trapeze artists’ equipment: paradoxically, lower weight proofing is the more challenging test between the two, as it calls for finer, more precise testing equipment.

Safety & Reliability

All testing is fulfilled at Reliance Hexham’s premises where our experienced and certified personnel uses advanced testing and precision equipment to ensure the maximum safety and reliability of our testing results.

Our team of specialised tradespeople will be able to provide dedicated advice for your specific application and requirements, and is always at your disposal for consultations or quotation requests.