As the name suggests, balance ropes serve the purpose of helping balance the hoist rope weight

Balance ropes are implemented in friction-type hoisting shafts that use Koepe-type winders. As the name suggests, balance ropes serve the purpose of helping balance the hoist rope weight.

To achieve balance, friction hoist systems employ a balancing load or, alternatively, two cages(conveyances), which are connected by means of a balance rope that matches the weight of the hoist rope to stop it from slipping.

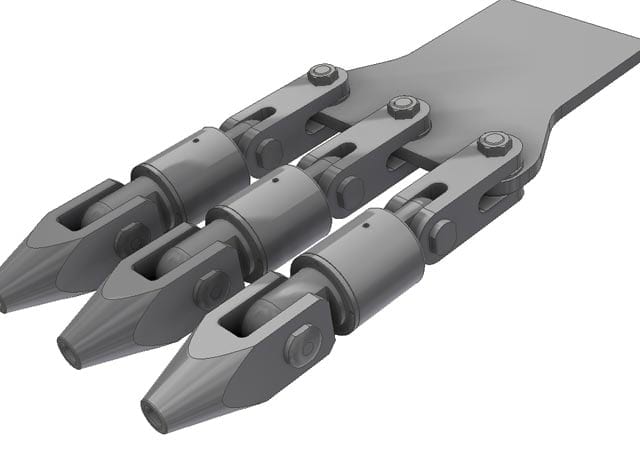

The balance rope is secured to the bottom of the conveyance or transporter by means of rope attachments, which take the name of balance rope attachment or tail rope attachment.

The applicable Australian regulatory framework is provided by AS 3637 Underground Mining–Winding Suspension Equipment series of standards, which covers manufacture, usage and testing of mine lifting components, including rope attachments.

Notably, attachments come with a recommended service life length and are required to be discarded on or before its completion.

Components of a string of balance rope attachments can include:

- Inverted Wedge Capels

- Rope Sockets

- Swivels

- Pins

- Chase Blocks

- Drawbars

If you are interested in other types of rope attachments, please visit their dedicated pages:

Rope Attachments Services

Reliance Hexham has facilities to undertake all aspects of rope suspension equipment supply for the Australian & International Mining industry.

We are specialised in custom solutions and offer expert design, manufacture, testing and refurbishment services for balance rope attachments.

This includes the latest 3D drawing programmes, CNC machining, forging, heat treatment and nationally accredited proof load and magnetic particle testing facilities.

Rope Attachments Design

Attachments represent the core of our business. We are proud to provide tailored design and engineering solutions leveraging our Engineering Team’s professional qualifications and extensive experience.

We follow a unique design and quality control process to ensure that your product is always delivered accurately, on schedule and compliant with all the appropriate guidelines and regulations.

Rope Attachments Manufacturing

Reliance Hexham delivers rope attachments as designed in-house or following an existing design, with a team of specialised Tradespeople that have over 165 years of experience between them.

Our attachments are made from high-grade materials and offer safety, ease of use, and reliability. Among our services, we likewise provide heat treatment as per Standard requirements. Every rope attachment is heat treated by quenching in water for hardening, and finally tempered to achieve the required minimum 500MPa tensile mark. Samples are then tested to verify results under our NATA accreditation.

Rope Attachments Testing

The Standard mandates that balance ropes and their attachments are to be systematically inspected, maintained, and, at a specified frequency, measured for wear and tested. Routine inspections must check for deformation, corrosion or other visible imperfections.

Reliance Hexham is NATA- accredited to offer a range of both Destructive Testing and Non-Destructive Testing and issue the relevant certification:

- Proof Load Testing – as per Australian Standard requirements, all components of attachments in mining must to be designed for a minimum safety load factor of 10 and 15 where applicable.

- Magnetic Particle Testing for cracks – if cracks are indeed found, attachments should not be repaired but rather substituted due to significant safety risk

All rope attachment testing is conducted on Reliance Hexham’s premises, where our experienced and certified personnel uses advanced testing and precision equipment to ensure the maximum safety and reliability of our results.

During the testing process, your equipment is carefully cleaned from rust, dust and any other foreign material in order to maximise its service life, and returned to you in its best achievable condition.

Rope Attachments Refurbishment

As per AS 3637.1 rope attachments require ongoing inspections and maintenance.

These attachments should be subjected to three basic levels of inspection:

- Daily Examination – Visual inspection for obvious defects by the operator.

- Field Examination (once a month between close examinations) – Cleaned and visually inspected for flaws, cracks, wear and deterioration.

- Close Examination (once every 36 months for balance rope suspension equipment) – Removed from service and , where appropriate, completely dismantled, thoroughly cleaned and degreased, and all Type A components should be non-destructively tested and components of the assembly should also be visually inspected for signs of wear, stepping, scoring, scuffing, fretting, pitting and corrosion.

Maintenance and discard provisions include:

- Worn or damaged pins shall be discarded and replaced.

- Holes may be recovered by bushing if the required conditions of the standard are met.

- Replacement components, made in accordance with the standard, shall be subjected to the assembly tests specified by the standard.

Reliance Hexham has a rigorous assessment process in place for attachments undergoing refurbishment refurbishment. Using a tablet device and a smart form, the attachments are visually examined and wear measured as per the requirements of the AS 3637 standard series. All measurements are taken by qualified tradespeople, using calibrated equipment, to determine if the components are within the allowable wear limits, they can then make a recommendation to discard, repair or recertify the component.

The attachments are also blasted, heat treated, tested and protective coated before being put through a final inspection process also using the tablet and smart form. This final inspection ensures all processes have been completed to the relevant components and the work has been completed to the required standard. The customer also receives certification at the completion of the job for the testing that has been conducted for their records. All our activities are supported by our management system which is certified to ISO 9001:2015.

Shaft Lifting Equipment

Reliance Hexham also design, manufacture, test and refurbish other shaft lifting equipment, including transporters, shaft conveyances and counterweights.

Through our close collaboration, our partner company A. Noble & Son Ltd can offer a range of wire rope solutions for both open cut and underground mining.

Our team of specialists will be able to provide dedicated advice for your specific application and requirements, and is always at your disposal for consultations or quotation requests.