Heat treating is a controlled group of processes aiming to change one or more mechanical properties of a metal or alloy by altering its microstructure

As the name suggests, heat treatment employs furnace heating, often at extreme temperatures, followed by water or oil cooling, in order to achieve the desired component characteristics.

Differently from other metalworking processes, heat treatment is carried out while the metal is in its solid state, a technique that allows to safeguard its existing shape. Properties that can be imparted via heat treatment range from tougher, stronger, and more resistant to dynamic loading forces.

Yet another use of heat treatment is stress relieving after welding.

Benefits of post weld heat treatment include the release of residual and thermal stresses, tempering, and an overall improved metallurgical structure.

When executed correctly, heat treatment can greatly benefit the working life of a component, significantly reducing operating costs and programmed downtime.

The most common use of heat treating is metallurgical. Common heat treatment techniques include annealing, tempering, normalising and quenching, depending on the desired end results.

Heat Treatment Services

Reliance Hexham has been providing a range of heat treatment services since 1989. Our experience comprises a wide range of market segments such as construction, mining, metal manufacturing, specialised lifting and materials handling.

Our work in close collaboration with our clients has generated a wealth of experience in this field. Our personnel are highly-trained in heat treating processes and have the knowledge to deliver consistent results and help you optimise the characteristics of the end product.

Furthermore, our engineering team is available for consultations on how to best realise your project.

Reliance Hexham provides the following heat treatment services:

Hardening and tempering

- Hardening is used to impart a higher resistance against physical deformation to a component. Tempering removes the stress and brittleness caused by quenching; the process entails reheating the metal to a specific temperature after it has been hardened and subsequently quenching it to refine the structure.

Stress relieving

- Minimising internal residual stress in the component structure is essential in reducing the risk of dimensional changes, which may happen during further manipulation or final employment of the item. This step may be necessary after processes such as welding, machining, or cold rolling. Stress relieving involves heating a metal part below its lower critical temperature and is recommended by Reliance Hexham during the recertification of components.

Normalising

- Normalising improves the machinability of ferrous alloys by giving them a uniform structure and curbing excess softness and is therefore performed on components that will be subjected to machining. The process involves heating the part to a set temperature, which is maintained for a period of time, after which the part is allowed to cool in air.

Annealing

- Annealing involves heating a metal above its re-crystallisation temperature, soaking it at that temperature, and then slowly cooling it in the furnace after the latter has been switched off. This process increases the ductility, while at the same time reducing its hardness, making it more suitable for further manipulation. Benefits include reduced load and energy requirements, and increased tolerance to large strains without experiencing failures.

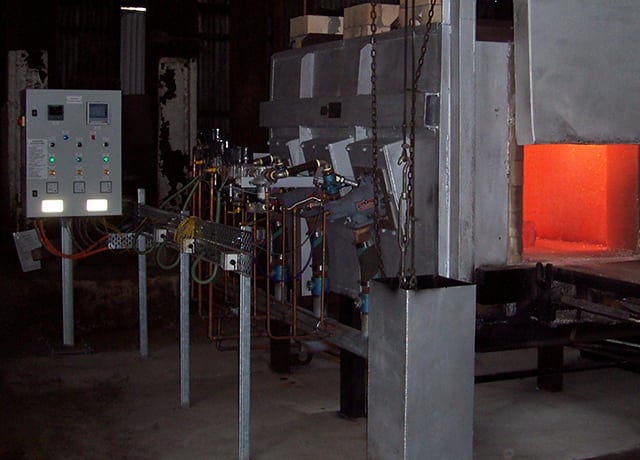

Our gas furnaces guarantee a more accurate, even heat treatment process.

The electronic recording system produces an accurate graph and reporting of the heat treatment process and this documentation can be provided on request.

The dimensional capacity of our furnaces are as follows:

Furnace 1 – 1680mm L x 620mm W x 500mm H

Furnace 2 – 1600mm L x 900mm W x 450mm H

NATA accredited non destructive testing facilities are available to verify tensile strength of heat-treated equipment.

Do you have any questions or need clarifications? Our expert team is at your disposal for consultations or quote requests. Please do not hesitate to contact us to discuss your individual requirements.