All testing conforms to the requirements of ISO 17025 and the NATA Scope of Accreditation held by Reliance Hexham

Destructive Testing

Destructive Testing measures the physical properties of a material, including but not limited to, resistance to impact, yield strength, and ultimate tensile strength. DT is also employed for testing of the safety factor of equipment; this verifies the ratio between common usage stress and failure point.

Non Destructive Testing

Non-Destructive Testing (NDT) evaluates a range of physical and functional properties of a test subject, be it a component or a unit of equipment. As the name suggests, in the process of testing, NDT does not permanently impact the test subject’s fitness to work. This type of testing is, therefore, suitable to mass-produced goods and one-of-a-kind pieces of equipment alike.

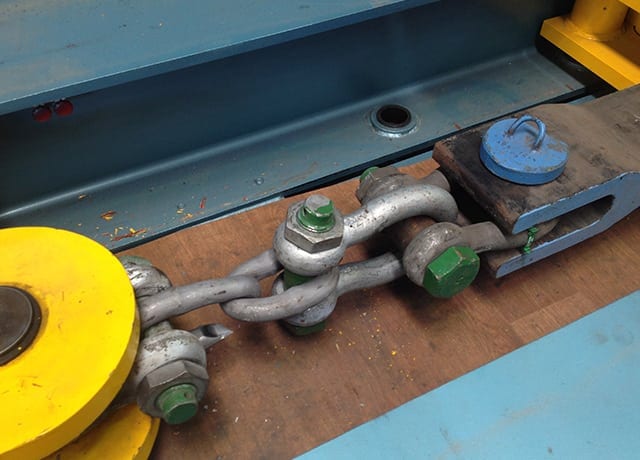

Proof Loading Testing

Proof load tests, or simply proof tests, constitute a fundamental testing method for any load-bearing structure and rigging setup. The goal of a proof test is to verify the fitness and resistance to strain of equipment used to lift, move or sustain whichever type of weight or mass; this test can be carried out on a single unit (either new or already in service) or on a full product line.

Magnetic Particle Testing

Excessive strain and repeated heavy use of equipment may cause dangerous discontinuities to form which, with time, can lead to irreversible fatigue cracks and even full breakage. Flaws can also develop during the hardening process of material if this is carried out incorrectly. In order to pre-empt costly and hazardous incidents, a magnetic particle test is recommended. Also known as magnetic particle inspection or MPI, this is a non-destructive type testing (NDT) implemented to discover cracks and other discontinuities on or near the surface of ferromagnetic and electrically conductive materials, and is one of the most used techniques to this end.

Function Testing

Function testing, or functional testing (FCT), is the process whereby a piece of equipment is tested by simulating its performance in its final working environment.

Liquid Dye Penetrant Testing

Originating from the railway industry of the early 1900s, Liquid Dye Penetrant Testing is a widespread crack testing method that goes by many names: dye penetrant inspection (DPI), liquid penetrate inspection (LPI), penetrant testing (PT) or simply dye-pen (DP). A versatile, quick, and cost-effective method to locate surface cracks, it is a Non-Destructive Test (NDT) type technique which does not impact the specimen’s properties and future fitness for use.

Dedicated Advice

Our team of specialists will be able to provide dedicated advice for your specific application and function testing requirements, and is always at your disposal for consultations or quotation requests